|

Condensate Polishing Plants (CPP)

CPP is employed to prevent return steam

condensate contaminants and corrosion products from entering into the

Turbine / Boiler. CPP overall reduces the

operating cost of power plant by improving its efficiency.

| These systems are used mainly in large size power plants to increase the overall boiler efficiency by polishing the condensate thereby making it fit for recycling. The improved quality of condensate duly polished reduces scale formation inside the boiler tubes, which in turn results in higher steam generation and effects better economics. |

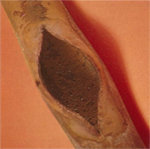

Boiler Tube Failure due to deposition &

Corrosion Boiler Tube Failure due to deposition &

Corrosion

|

Working of Condensate Polishing CPP

- Removes TDS from Cooling Water ingress or from Make-Up Water

- Removes Iron/ Copper Oxides to prevent Boiler Corrosion

- Removes Silica from Make-Up water to prevent any deposition or corrosion in Turbine

- Removes Weak Acids & Organics from Make-Up water or Boiler Additives

- Reduces the consumption of Chemicals (Ammonia/ Ammine, etc.)

- Reduces the Blow Down Volume

As an exclusive licensee of Termomeccanica, Italy, the World Leader in Condensate Polishing Plants, we offer the complete range of CPP's for sub and super critical power stations.

|